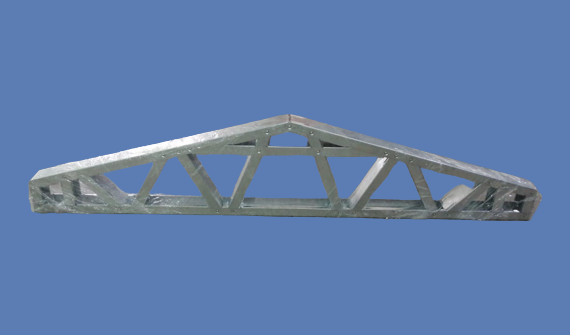

A gable truss is a key element in roof construction, commonly made using steel components. It is characterized by its triangular shape and is used to support the sloping ends of a pitched roof. Gable trusses consist of steel members connected in a triangular configuration, providing excellent strength and stability to the roof structure. The steep angles of the triangles efficiently distribute the weight of the roof and any external forces, such as wind or snow loads. This design allows for clear spans, reducing the need for interior supports and maximizing the usable space inside the building. Steel gable trusses offer several advantages, including their high strength-to-weight ratio, durability, and resistance to corrosion and decay. These qualities make them a popular choice for a wide range of construction projects, from residential homes to commercial and industrial buildings.

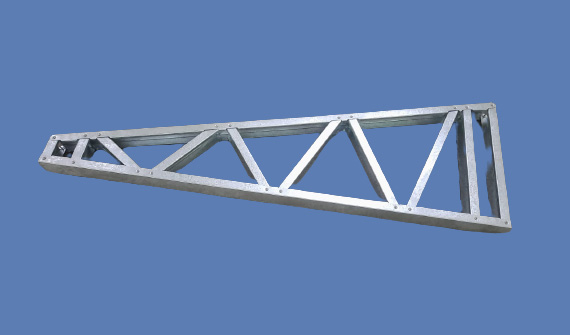

Mono Truss

Mono trusses, also known as mono-pitch or single-pitch trusses, are another type of roof truss commonly constructed using steel. These trusses feature a single sloping plane, with one end higher than the other, allowing for different eave heights. Steel mono trusses are often used in building extensions, lean-tos, or additions to existing structures. The steel components are fabricated in a triangular arrangement, providing the necessary support and stability to the roof. Steel mono trusses offer the advantage of being lightweight yet robust, making them easy to transport and install on-site. The design versatility and quick assembly process make steel mono trusses a cost-effective solution for various architectural configurations. Additionally, steel's inherent resistance to weathering and corrosion ensures a long-lasting and reliable roofing system for the building.

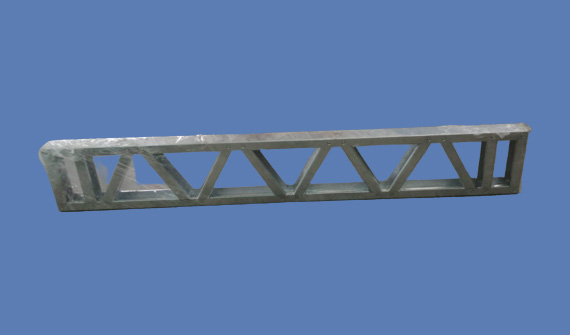

Floor trusses made of steel are an integral part of modern building construction. These trusses consist of steel beams and joists arranged in a grid pattern to create a sturdy and efficient flooring system. Steel floor trusses have replaced traditional wood joists in many applications due to their superior strength, durability, and design flexibility. The use of steel in floor trusses allows for longer spans, reducing the need for additional support columns and providing open and uninterrupted spaces within the building. These trusses can be prefabricated off-site, ensuring precision and quality, and then assembled quickly on-site, expediting the construction process. Moreover, steel floor trusses are resistant to moisture, fire, and pests, offering a longer lifespan and requiring less maintenance compared to traditional materials. The combination of strength, ease of installation, and long-term durability makes steel floor trusses a preferred choice for modern construction projects across various industries.

Features

Strong load-bearing capacity: Even the earliest wood truss bridges were built to distribute weight evenly. With this intention in mind, bridges could be built for larger loads. Overall, this makes this bridge design a very strong and dependable option. With steel construction, truss bridges can take on the traffic of today.

Effective use of materials: What makes truss bridges relevant more today than ever is their effective use of materials. Keep in mind, fewer materials mean easier construction and less money spent.

Affordable to construct: Because of the simplicity of truss bridge designs, they are often a great fit for accelerated bridge construction. In order to improve construction time, each steel piece can be quickly pieced together.

Versatile and adaptable design: While truss bridges are great for short spans, what makes them versatile is their ability to go long distances and still support large loads. With the polygonal design of the truss, it’s possible to cover long distances. Truss bridges can be needed in areas with extreme weather. Despite the harsh weather, with great structural engineering, our truss bridges are prepared to last even the worst storms for decades to come. When it comes to crossing a treacherous area, truss bridges can be built to keep communities connected.

Professional bridge engineering: While truss bridges may seem simple, they are quite intricate and require complex engineering and design. Because the weight must be distributed away from the center beam, each truss must be optimally engineered to distribute the weight. Without attention to detail in the engineering design, the truss design will not be nearly as effective.